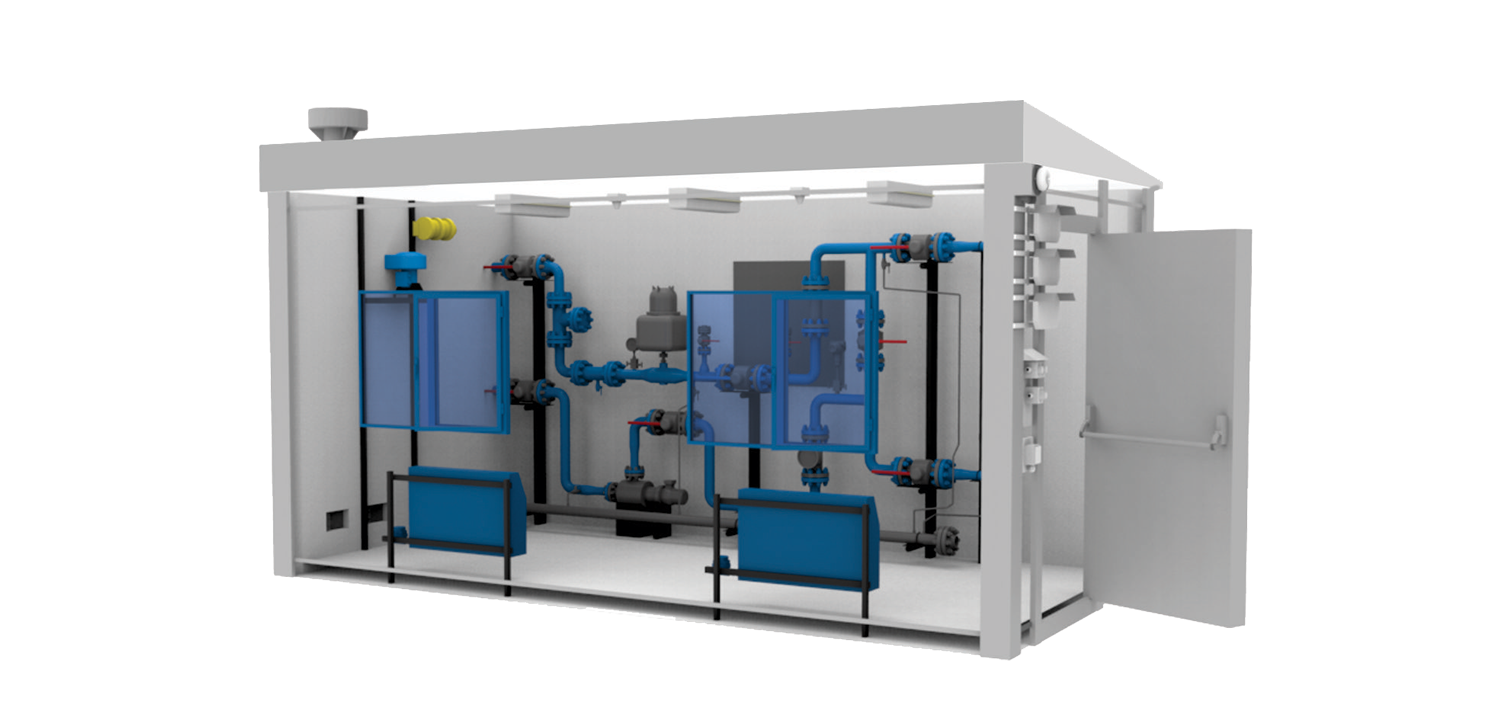

Oil quality system

PURPOSE:

Sampling skid is provided:

-

for hand and mechanical oil sampling;

-

for measurement and control of physical and chemical properties;

-

for issue the information on density, humidity content, viscosity, pressure and temperature of oil transferred.

Sampling skid in accordance with international standards:

-

The oil shall be taken to sampling skid via sampling apparatus.

-

The value of oil flow via sampling apparatus shall meet international standards. Oil flow via in-line transducers (density, viscosity, humidity content) shall meet the requirements of operational documentation for data of transducers.

-

Estimation conformed the provision of required flow value via sampling skid shall be specified in design documentation.

-

Sampling skid shall be fabricated in factory environment and allocated in premise with temperature from +150C to +350C. Allocation of sampling skid in the same premise together with test line package is allowed.

-

Engineering systems of the premise shall provide the sampling skid with operating conditions as specified in Technical Design Assignment as well as its safety.

Standard set.

Sampling skid shall be equipped with:

-

in-line density transducers;

-

in-line humidity content transducer;

-

in-line viscosity transducers, if required (viscosity transducers can be excluded from the composition of sampling skid if in-line flow meter is used, viscosity changes don’t have an influence on error);

-

temperature transducer and thermowell for temperature gage;

-

pressure transducer and pressure gauge;

-

automated sampling apparatus in accordance with international standards providing the sampling by set program with sealed containers vol. at least 3 liters (operating and spare);

-

device for manual sampling of snap samples in accordance with international standards;

-

recycling pump providing the required oil flow via sampling skid (if pumping diagram available);

-

flow meter (in-line flow meter);

-

oil-flow controller via sampling skid, if required;

-

flushing system for in-line transducers, if required;

-

filters, if required (operating and spare);

Additional measuring devices for oil quality performances can be included in sampling skid (analyzers of salt, sulphur, moisture, chloride salts, mechanical impurities, paraffin, H2S, methyl and ethyl mercaptans, non-associated gas, saturated vapors content, viscometer and other measuring devices in accordance with regulatory documents).

In-line densiometer is allowed to be switched off, included in sampling skid, while measuring of oil mass by direct dynamic method, meanwhile it shall make provision a place of connection of density transducer for checking and control of MX mass flow transducers.

Engineering systems placed in sampling skid premise shall provide:

-

artificial illumination at least 100 luxe;

-

automated temperature regulation in the premise within prescribed limits;

-

exhaust ventilation by full airspace;

-

mechanical exhaust ventilation with periodical operation supplying eightfold air exchange within an hour by full airspace, it shall be switched on automatically (once gas pollution reaches 20 % out of lower explosive limit) or manually using push-button station allocated outdoor next to main entrance of the premise;

-

automated shutdown of all electrical loads (except of blowers) once gas pollution reaches 40 % out of lower explosive limit for trunk oil pipelines and 50% - field oil pipelines;

-

control over the gas pollution and fire with appropriate light and audible alarm outside the premise close to main entrance and on a light annunciator in Control Room.

Sampling skid shall include the following:

-

unit to install the pycnometer on the line of density transducer;

-

oil density measuring point using areometer.

Features:

-

Drain system shall be closed. Ball valves shall be provided in upper points of process piping.

-

Full bore ball valve shall be applied in process piping of in-line transducers and equipment of sampling skid.

Our projects

Useful

Reviews

Head count

-

Как Вам наш сайт ENGLISH?

Нравиться 0 (%) Не нравиться 0 (%) Воздержусь 0 (%)